Views: 0 Author: Site Editor Publish Time: 2026-01-13 Origin: Site

Ever wondered how to join acrylic sheets seamlessly? Whether you’re working on a DIY project or a commercial application, knowing the right techniques is key.

In this article, we’ll guide you through the best methods for joining acrylic sheets—from solvent welding to adhesives and mechanical fasteners. You’ll learn which technique suits your project, ensuring a strong, lasting bond.

Method | Description | Best Use Case | Pros | Cons |

Solvent Welding | Uses a solvent to bond acrylic sheets. | Permanent joins for clear and smooth edges. | Strong, seamless bond, ideal for precision work. | Requires good ventilation, can be messy. |

Acrylic Adhesives | Special adhesives formulated for acrylic bonding. | General use for transparent or colored sheets. | Clear, strong bond with minimal drying time. | May require clamps and precise application. |

Mechanical Fasteners | Uses screws, bolts, or clips to hold sheets together. | Temporary or adjustable joins. | Easy to use, removable. | May require drilling and can cause cracking. |

Solvent welding is one of the most effective methods for joining acrylic sheets. This technique uses a solvent, such as acetone or methyl methacrylate (MMA), to dissolve the edges of the acrylic. When the solvent is applied to the edges, it softens and melts the acrylic, allowing the two sheets to fuse together as they dry. The result is a clear, strong bond that is almost indistinguishable from the rest of the sheet.

To ensure the bond is strong, apply a thin layer of solvent evenly along the joint and press the acrylic sheets firmly together.

For those who prefer a less chemical-heavy approach, acrylic adhesives are an excellent option. These adhesives are specially formulated for bonding acrylic sheets and can create a strong, clear bond. Unlike solvent welding, acrylic adhesives do not require the sheets to be dissolved but instead rely on a chemical bonding process.

When using acrylic adhesive, ensure both surfaces are clean and free from dust or oil to achieve the best results.

In some cases, using mechanical fasteners such as screws, bolts, or clips is the best way to join acrylic sheets. This method is commonly used in temporary applications or for creating a removable joint. While this method is easy and quick, it may require drilling holes into the acrylic, which can be challenging without the proper tools.

Before joining acrylic sheets, it’s crucial to clean the edges to ensure a strong bond. Use a soft cloth and a gentle cleaner to remove any dust, oil, or grease. Even a small amount of contamination can weaken the bond, especially when using solvent welding or adhesives.

For the best results, clean the edges using isopropyl alcohol, as it evaporates quickly and leaves no residue.

Proper alignment of the acrylic sheets is critical for a seamless join. Use a square or a straight edge to ensure the edges of the sheets line up perfectly. Misalignment can result in uneven bonding or gaps that affect the overall appearance of the project.

Use clamps to hold the sheets in place while the adhesive or solvent sets. This ensures the acrylic remains aligned during the bonding process.

Tool/Material | Description | Best Use Case | Tips for Use |

Solvent (e.g., Acetone) | Chemical used for solvent welding. | Joining clear acrylic sheets. | Apply with care to avoid excess or spill. |

Acrylic Adhesive | Special adhesive designed for acrylic bonding. | Joining acrylic sheets of various thicknesses. | Use sparingly to avoid messy results. |

Drill and Screws | Used for mechanical fastening. | Temporary or adjustable joints. | Use a drill designed for acrylic to prevent cracks. |

Clamps | Used to hold sheets together while bonding. | Essential when using adhesives or solvent. | Ensure even pressure across the joint area. |

First, cut the acrylic sheets to the desired size. Ensure that the edges are straight and smooth, as rough edges can cause an uneven bond. It’s helpful to use a fine-toothed saw or a laser cutter for precise cuts.

Use a fine-grit sandpaper to smooth the edges of the acrylic sheet after cutting. This ensures that the solvent can adhere properly to the surface.

To join the sheets, apply a thin layer of solvent to the edges of the acrylic. Be careful not to use too much solvent, as this can cause excess dripping or an uneven bond. Once the solvent is applied, press the sheets together and hold them in place for a few minutes.

Work in a well-ventilated area when using solvents, as the fumes can be harmful. Always wear protective gloves and goggles.

When selecting an acrylic adhesive, ensure that it is specifically formulated for use with acrylic. Some adhesives may work well with other plastics but not with acrylic, which has unique chemical properties. MMA-based adhesives are commonly used and provide a clear bond.

If you need a strong, fast-drying adhesive, look for one that has a longer curing time to allow for adjustments during the application process.

Apply the adhesive evenly on the edges of the acrylic sheets. Press the sheets together firmly and hold them in place for the recommended time stated on the adhesive's instructions. Ensure that the adhesive is evenly spread and that no air bubbles form during the bonding process.

Use a syringe or applicator bottle for precise control over the amount of adhesive applied to the acrylic sheet.

When using mechanical fasteners, it is essential to choose the correct type of fastener to avoid damaging the acrylic sheet. Stainless steel screws, bolts, or even rivets work well because they don’t react with the acrylic, which can cause discoloration or stress cracks.

Use flat-head screws to minimize the risk of scratching the surface of the acrylic sheets. Consider using rubber washers to prevent cracking under pressure.

Before securing acrylic sheets with fasteners, mark the spot where you want to drill the holes. Use a drill bit specifically designed for acrylic to avoid cracking. Once drilled, align the sheets, insert the fasteners, and tighten them to secure the sheets together.

Always drill slowly and steadily to reduce the chance of cracking, and avoid over-tightening the fasteners.

When working with acrylic sheets, especially when using solvents or adhesives, safety is paramount. Always wear protective gloves, goggles, and a mask to prevent skin contact with chemicals and to avoid inhaling fumes.

Keep a fire extinguisher nearby when using flammable solvents or adhesives, especially in poorly ventilated areas.

Ensure you work in a well-ventilated area to avoid inhaling harmful fumes. Set up your workspace by laying down a clean, flat surface and using clamps or supports to hold the acrylic sheets securely in place.

If possible, work outdoors or in an area with good airflow to reduce the risk of solvent inhalation.

One common mistake when joining acrylic sheets is applying too much solvent or adhesive, which can weaken the bond or cause the acrylic to melt. Use a minimal amount of solvent or adhesive to achieve the best bond.

Test the solvent or adhesive on a scrap piece of acrylic first to ensure it doesn’t cause any damage or discoloration.

Improper alignment of the sheets during the bonding process can lead to uneven joins. Always check that the edges are properly aligned before applying any bonding materials.

Use a square or measuring tape to double-check the alignment before starting the bonding process.

Joining acrylic sheets requires the right techniques, including solvent welding, adhesives, and mechanical fasteners. These methods ensure a strong and durable bond. Likebond Co., Ltd. offers high-quality acrylic bonding solutions that provide excellent strength and clarity, making them ideal for various applications in commercial and DIY projects. Their products help create seamless, professional joins with long-lasting results.

A: To join acrylic sheets, you can use methods like solvent welding, acrylic adhesives, or mechanical fasteners. Each method depends on your project needs and the type of acrylic used.

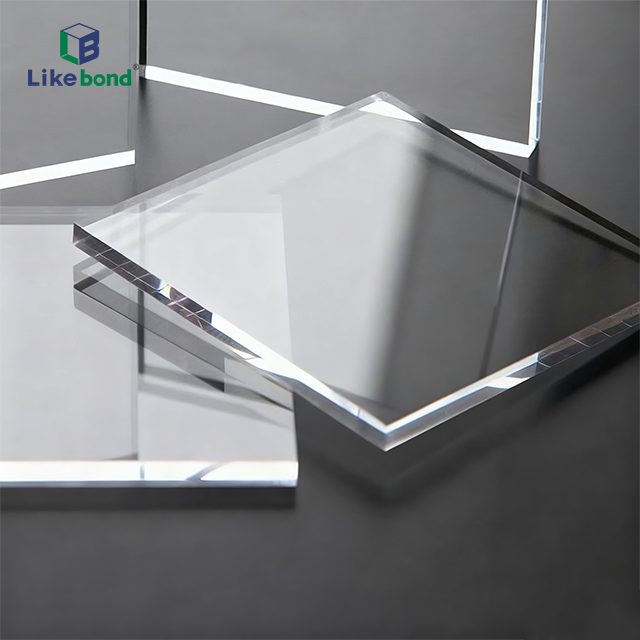

A: Yes, clear acrylic sheets are perfect for windows. They provide high clarity and durability while being lighter and more impact-resistant than glass.

A: You can find acrylic sheets near me at hardware stores, plastic suppliers, or online retailers offering a range of acrylic sheets, including 4x8 acrylic sheets.

A: Acrylic adhesives designed specifically for acrylic sheets are best for creating clear, strong bonds. MMA-based adhesives are highly effective for permanent joins.

A: Yes, acrylic sheets can be joined with screws, bolts, or clips. This method is ideal for temporary or adjustable joints but requires careful drilling to avoid cracking.